YUTONG NEW ENERGY BUSES AND SOLUTIONS

Buses Development

- Hybrid bus

- Full electric bus

- Fuel cell buses

Integrated Solutions

- Bus development and manufacturing

- Recharging facility construction

- Informationized management operation

- Financing & procurement services

In 1999, Yutong developed the first full electric bus.

In 2005, Yutong developed the first hybrid bus.

In 2012, Yutong hosted and was involved in nine new energy bus projects of China’s 12th Five-year Plan. The energy-saving and new energy bus base with an investment of 3.86 billion yuan was partially put into operation. Its annual planning.

In 2013, Yutong officially launched ReCtrl technology which can accurately judge the real-time state of vehicles and intelligently match the optimal power combination.

-

In 2014, Yutong officially launched the integrated solution of full electric buses which solves customers’ problems on products, supporting facilities, services, financing and so on, actively promoting the marketization process of new energy buses.

In 2014, the National Engineering Technology Research Center for Electric Bus Control and Safety was designated to be located in Yutong, marking the recognition of Yutong’s ability and position on electric bus technology.

In 2015, Yutong delivered 21,221 units of energy-saving and new energy buses.

In 2016, Yutong delivered 26,856 units of energy-saving and new energy buses. The Energy-saving and New Energy Bus Key Technology Research & Development and Industrialization Project was granted China's National Science Progress Second Award, and Yutong is the only bus maker who won the prize.

- 1999

- 2005

- 2012

- 2013

- 2014

- 2015

- 2016

Yutong New Energy Buses

CORE ADVANTAGES

Through the light-weighting technique, intelligent control, high-efficient electric drive and braking, high-efficient electrical accessories, and other technologies to ensure the ultra-low energy consumption of E-series products.

Concerning the costs arising from the operation, repair, maintenance and so on, the LCC management can effectively control the overall costs and is helpful in reducing them so as to enhance the profitability and create new development growth point.

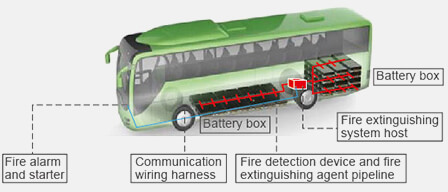

All new energy products can meet the 3S safety technical requirements of electronic control center —— fire-resistant, water-resistant and electric shock--resistant, thus ensuring the safety of vehicles and passengers.

Yutong can provide you with driving training, fleet management, financing solutions, recharging station construction, profit-making mode, intensive management as well as remote data transmission, monitoring, vehicle selection and so on.

-

Low energy consumption

-

Reduced costs

-

Good safety

-

Integrated solutions

Watch the Video

YUTONG NEW ENERGY BUSES

Featuring advantages of low energy consumption and low emissions, Yutong new energy buses have become the preferred choice of the transportation energy transformation.

-

ICE12 Intercity bus version

-

E12 City bus version

-

H12

OPERATING CASES AT HOME AND ABROAD

As of 2016, Yutong has totally delivered 54,000 units of energy-saving and new energy buses, which can be seen in Paris, Strasbourg, UK, Poland, Iceland, Qatar, Macau, Taiwan, China mainland and so on.

- Paris , France

- Lyon , France

- Shanghai , China

- Tianjin , China

In February 2016, a Yutong 12-meter low-floor full electric bus conducted test run on route 21 and route 147 in Paris, France.

Under the condition of traffic congestion, the average speed of the bus was 8km/h. Under the outdoor temperature of 2~10℃, the air conditioner, defroster and heating were turned on and the bus was fully loaded or overloaded in most of the time.

Every day, it worked 12 hours 48 minutes and ran 107.09km. The SOC value was bigger than 50% when the daily operation of the bus was finished.

In June 2016, a Yutong 12-meter low-floor full electric bus conducted test run on route C7 and route 45 in Lyon, France.

The average speed on the routes was 10.93km/h. Under the condition of turning on the air conditioner, the driving range of one-time charging could meet the requirements of one-day usage.

In April 2015, 200 units of full electric buses owned by Shanghai Bus Company were put into operation.

Under the actual operating condition, the driving range of one-time charging reached more than 250km that met the needs of public transport. The average power consumption of DC side was 84.07kWh/100km.

In August 2012, 10 units of 12-meter full electric buses were put into operation in Tianjin with an average daily operating mileage of 220km and an average power consumption of 0.9kWh / km.

In December 2013, 47 units of 12-meter full electric vehicles were put into operation in Tianjin with an average daily operating mileage of 190km and an average power consumption of 0.92kWh / km.

Q&A ABOUT YUTONG NEW ENERGY BUSES

- Are electric buses safe?

- Do the batteries need to be replaced every two or three years?

- How well is the power performance of electric buses? Are the acceleration and gradeability good enough?

- Can the batteries last one day after being fully recharged?

- How high is the failure rate of batteries?

- What are the advantages of Yutong full electric buses?

Are electric buses safe?

1. The integrated system safety technology improves the safety of vehicles.

The structural safety design, high-voltage safety design and functional safety design are taken into account during the engineering so as to improve the safety of vehicles through pre-warning, protection, fault monitoring and diagnosis, etc. With the integrated design of electric control system, the high-voltage connecting points are reduced to 14 from 29, which effectively ensure the safety and reliability of vehicles.

2. Structural safety

The structural design of annular frame members features the small deformation and large survival space amid a collision and the good safety performance amid a rollover. The rollover angle of E7 is 45 degrees, much higher than the value of 28 degrees stipulated by Chinese national standard.

3.Protection safety

The protection level reaches IP67 and the fording depth is higher than that of conventional buses.

The key parts like electric motors, electric controllers, etc. adopt water cooling design. With optimized package of whole vehicles, the fording depth is higher than that of conventional buses, taking a lead in China’s bus industry.

The sound passive safety measures ensure the safety of passengers in emergency situations, such as the physical isolation between the battery compartment and the passenger compartment.

4.The batteries that have been repeatedly verified, featuring good safety and reliability.

The battery has passed the destructive tests like heating, short-circuit, pressing, immersion, overcharging, impalement and so on, and also passed the verification of QC/T 743-2006 standard on lithium ion dynamic test.

The Battery Management System (BMS) is a system that can monitor the temperature, voltage, electric current and electric quantity of each monomer, and equipped with corresponding warning function to meet the requirements of all kinds of extreme conditions.

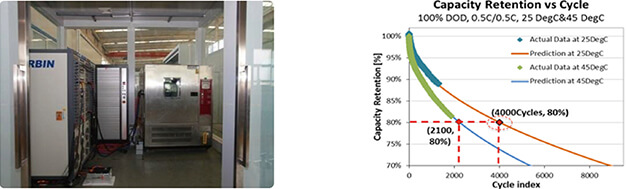

Do the batteries need to be replaced every two or three years?

The batteries have gone through strict incoming inspection to ensure the durability. The five-year warranty and eight-year extended warranty can be provided.

How well is the power performance of electric buses? Are the acceleration and gradeability good enough?

Yutong full electric buses are robust and meet the needs under normal road conditions. Seeing is believing.

Can the batteries last one day after being fully recharged?

Yutong has full range of full electric buses with diversified driving ranges, and you can surely find one that meets your requirements.

How high is the failure rate of batteries?

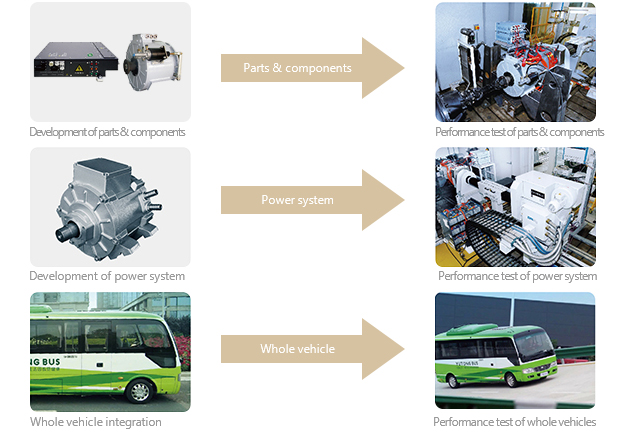

The three-tier verification system, namely verification of parts, power system and whole vehicle, effectively improves the reliability and durability of vehicles.

With abundant accumulation in technologies and manufacturing processes of conventional buses, the quality is worth of your trust.

Y.E.S (Yutong Electrocoating Standard)

Yutong Y.E.S technology enables the vehicle to have a salt spray resistance of more than 1000 hours, greatly enhancing the anti-corrosion performance and long-lasting beauty of vehicles.

Robotic welding

The robot welding features even welding spots, consistent welding seams, reliable welding quality and high welding efficiency.

Automatic painting technique

The automatic painting technique ensures the uniformity, finish degree and adhesion force of the paint film, and the film features better performance.

Sophisticated production line of E-series

The professional production line for new energy buses and careful assembling by top technical workers guarantee the quality of bus products.

What are the advantages of Yutong full electric buses?

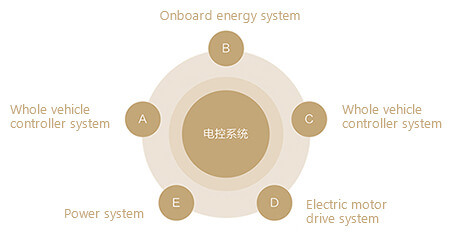

1. The electric buses are far from replacing conventional engines with electric motors and batteries.

The electric control technology is the core technology of electric buses which enables the whole vehicle control system, onboard energy system, electrical accessories, electric motor drive system and power system to work efficiently through the electric control system.

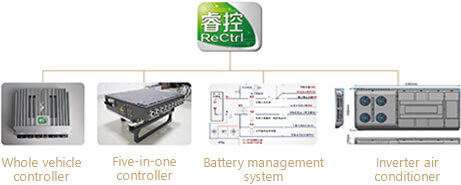

2.Yutong’s unique control system for electric buses —— ReCtrl: After being verified by over 10,000 buses in the market, the ReCtrl technology is proved to be intelligent, mature and high-efficient.

Taking whole vehicle controller, five-in-one controller, intelligent battery management system and inverter air conditioner as the core, Yutong ReCtrl forms a unique technical platform for full electric buses which has achieved prominent energy-saving effect in hybrid and plug-in hybrid buses, and also ensures the stability and efficiency of full electric buses.

3.Four electric technologies

Electric Drive

With high efficient electric motor instead of conventional automatic transmission, it can achieve the electric drive and stepless speed change, thus making drivers feel more relaxed. Meanwhile, it also cut the repair and maintenance costs of gearboxes and clutches.

Electric steering

Electric steering is an electric hydraulic power steering system. With the dynamic frequency conversion technology, it can meet the needs of power steering, making the steering easier and consuming less power.

Electric brake

The regenerative braking energy recovery technology of ReCtrl can transform the braking energy into electrical energy via the electric motor and store it in the batteries for the next drive. So the energy is regenerated and reused.

Electric air conditioner

The advanced inverter air conditioner with both cooling and heating functions can achieve the automatic adjustment of cooling capacity and control the temperature of different areas separately. Compared with the ordinary air conditioners for vehicles, it can save the power by 15%.

4.Four intelligent technologies

Intelligent energy management of whole vehicles

Conduct the integrated management on the energy consumption of the electric drive and electric auxiliary system through the whole vehicle controller and CAN network based on the running status of vehicles, so as to greatly improve the efficiency of whole vehicles and reduce the power consumption.

Inverter control and intelligentization of air conditioners

Adopt the advanced inverter control technology with CAN communications and the intelligent heat load sensing technology of compressors to achieve the automatic adjustment of cooling capacity and control the temperature of different areas separately. Compared with the ordinary air conditioners for vehicles, it can save the power by 15%.

Intelligent management of vehicles

Monitor vehicles through the internet and mobile phones, remote monitor the vehicle status as well as the current, voltage, temperature and insulation resistance of high-voltage components, and set up the hierarchical processing mechanism like fault alarm, shutdown, power outage and so on, so you can learn the operating status of vehicles conveniently.

Intelligent management of charging

With advanced automation technology and communication technology as well as combining the intelligent monitoring platform, the functions like the collection and handling of charging data, control and adjustment of charging machine, intelligent load adjustment, automatic charging and discharging, text message reminder, etc.

INTEGRATED SOLUTIONS

From financing program, power station construction, vehicle type selection to the operation, management and after-sales service of vehicles, Yutong provides you with integrated solutions, taking away all your worries.

-

Vehicle type selection

-

Station construction

-

Financing solutions

-

Intensive management and...

-

After-sales service

Vehicle type selection

Yutong has full range of full electric buses with 100~300km driving ranges, and you can surely find one that meets your requirements.

Station construction

Yutong can conduct professional assessment based on the transport needs, operational strength, stations distribution and other aspects of customers and provide them with individual charging station construction programs.

Yutong can tailor make the four systems for station construction according to your requirements, and enables you to have an easy operation.

4 systems of charging station construction

Charging system: Plan the ground area and decide the number of charging spots according to the number and types of vehicles

Power distribution system: Choose suitable site, design charging program and calculate the needed power supply capacity according to the number and types of charging spots.

Civil engineering system: Rain shed of charging spots; construction of supporting rooms

Monitoring system: Vehicle information monitoring; charging spot information monitoring; safety information monitoring

Financing solutions

Comprehensively analyze your financial needs and provide simple and efficient financing program to help you solve the funding needs in different phases.

Intensive management and remote data transmission and monitoring

By means of automotive electronics, electrical technology, whole vehicle integration, Internet of Things, cloud computing and other technologies, Yutong provides customers with advanced, stable and efficient fleet management system and cuts your operating costs.

Intelligent management of charging: Adopt advanced automation technology and wireless network communication technology to achieve the real-time data collection of vehicle charging process, charger remote control and regulation and automatic charging reminders, and provide a wealth of statistical statements serving as a strong support for the decision making of charging management personnel.

Scientific and intelligent of vehicle monitoring: Yutong has developed remote monitoring and diagnosis system which can monitor the real-time operation data of vehicles, and you can learn the various vehicle data such as real-time location, operation, battery, electric motor, electronic control unit and others. In addition, Yutong also set up the hierarchical processing mechanism like fault alarm, shutdown, power outage and so on. In case of a serious failure, text messages can be send to customers and related after-sales service people so as to address the problem as early as possible.

After-sales service

Yutong offers you "full-care" services provided by professional team starting from telling your intention on buying vehicles to move away your related worries.

1. Track the production

Grasp the sales trend of vehicles, track the production of vehicles and learn the vehicle performance and status in advance.

2. Delivery service

For every batch of new vehicles, Yutong will arrange specific people to follow the vehicles till they arrive the customers’ destination so as to ensure the smooth arrival of vehicles and personally hand over them to customers.

3. Service guarantee at customers’ location

For all new vehicles, Yutong will arrange specific people to stay at customers’ location, follow the vehicles and address the vehicle failure on site in a bid to ensure the normal operation of vehicles. In the whole life cycle of vehicles, Yutong provides free technical support.

4. Comprehensive training program

After the local service providers are trained by Yutong, they will work out a specific training program for customers and pay regular visits to customers so as to meet customers’ needs in different stages.

5. Professional service network

Set up professional service network of new energy vehicles, equip with professional testing equipments to provide customers with comprehensive operating guarantee. Provide one free PDI in a whole year and one free maintenance check within 30,000 km or 6 months as well as other service activities.

6. Spare parts storage guarantee

The well-established three-level spare parts storage network can fully meet customers’ demands on spare parts. For each batch of new energy vehicles, Yutong will work out specific storage plan for new energy system to ensure the availability of spare parts.

Yutong will continue to provide excellent management solutions for the whole process of customers’ operation, including intelligent transport management, intelligent safety management, intelligent energy consumption management, intelligent repair and maintenance management, vehicle remote control, remote upgrading of whole vehicle control unit and so on, to help customers use the vehicles more efficiently, more intelligently with lowered costs.

2010-2017 YUTONG All rights reserved.

ICE12 full electric intercity bus

Features: the fuel costs only accout for 20% that of diesel buses, greatly saving the operating costs; the stepless speed change reduces the labor intensity of drivers.

- Bus modelICE12

- StructureMonocoque

- SuspensionAir suspension

- Floor type3-step staircase

- Length (MM)12365

- Width (MM)2550

- Height (MM)3400

- Passenger quantity (person)59

- Battery volume (KWH)295kWh

- Driving range (KM)200(SORT 3)

E12 full electric city bus

Features: the driving range can meet the whole-day operation need; equippmed with high-end specification like alu-alloy air duct, alu-alloy armrest, follow-up dashboard, LCD electronic instruments, electric rearview mirror and so on; the key compenents like steering and alxes adopt world renowned brands that boast good reliability.

- Bus modelE12

- StructureMonocoque

- SuspensionAir suspension

- Floor typeLow floor

- Length (MM)12000

- Width (MM)2550

- Height (MM)3340

- Passenger quantity (person)92

- Battery volume (KWH)295kWh

- Driving range (KM)220(SORT 1)

H12 hybrid city bus

Features: its fuel consumption per 100km is 10L lower than that of diesel buses, featuring low operating costs; the stepless speed change reduces the labor intensity of drivers; no recharging is required, boasting high adaptability.

- Bus modelH12

- StructureMonocoque

- SuspensionAir suspension

- Floor typeLow entry

- Length (MM)12000

- Width (MM)2550

- Height (MM)3075

- Passenger quantity (person)92

- Battery volume (KWH)Super capacitance

- Driving range (KM)--